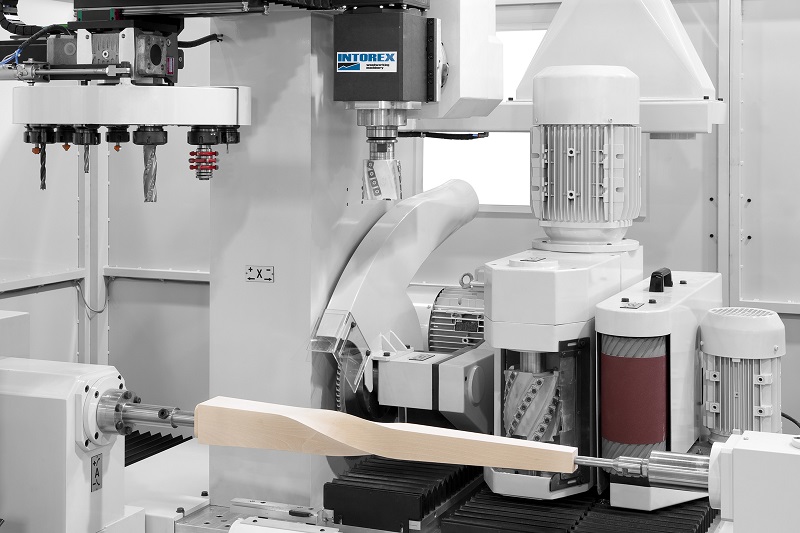

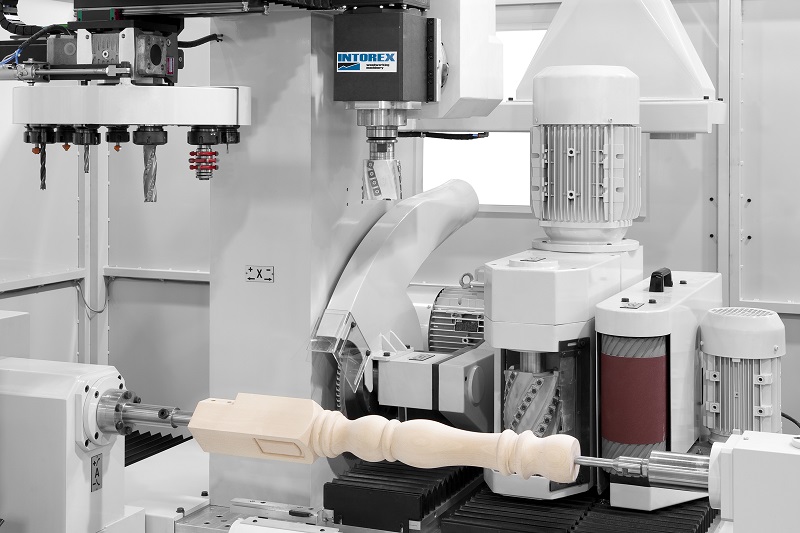

Cnc machining center of 5 interpolated axes and a total of 9. As standard the TMC is fitted with an automatic frontal hopper feed loader that delivers the blank between the headstock and tailstock where it is clamped. It is equipped with a saw blade head for producing a turned section of the component, a milling head for flat machining or stock removal and a sanding head.

In addition the TMC has an independent router head with a 10 position tool changer. This can be used for additional drilling, milling and shaping operations. Thanks to the sanding facility it is possible to produce a completely finished component that requires no further work or handling. Once the final machining or sanding operation is complete, the component is ejected on to a transfer exit belt.

On request the CNC machining center can be fitted with an additional table which can have either a pneumatic or mechanical clamping system. This table can be used in addition to the between centres machining. Obviously, this gives the capability to produce even a greater variety of components by just using the CNC router head.

TMC-1500 is capable of producing either turned or shaped furniture and joinery parts. Components such newel posts, stair spindles (with modern contemporary design), chair, table and sofa legs among others can all be produced on this machine.

Production 30% more efficient and more flexible with the fully machining process of turning, milling, drilling and sanding in one set-up.