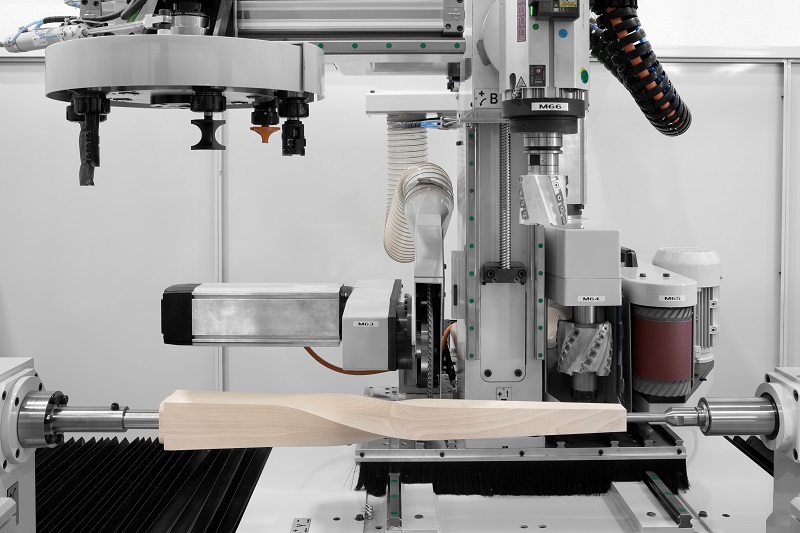

CNC wood machining centre of 5 interpolated axes and a total of 6. As standard the TKC is fitted with an automatic frontal hopper feed loader, a saw blade head for producing a turned section of the component, a milling head for flat machining or stock removal and a sanding head.

Thanks to the sanding facility it is possible to produce a completely finished component that requires no further work or handling.

Once the final machining or sanding operation is complete, the component is ejected onto a transfer exit belt. In addition, the TKC has an independent router head with a 8 position tool changer (drum type). This can be used for additional drilling, milling and shaping operations.

On request the TKC can be fitted with an additional sanding unit for the turned parts as well as an extra turning unit with “V” gouge. Obviously this gives the capability to produce even a greater variety of components by finishing either turned and shaped components.